Custom Injection Molding Services

Start A New Injection Molding Quote

STEP | STP | SLDPRT | IPT | PRT | SAT files

All uploads are secure and confidential.

Plastic Injection Molding Services for Custom Parts

Our injection molding process is streamlined to handle everything from plastic prototypes to production parts, with a standard lead time of 15 business days. For projects requiring faster turnaround, our quick turn injection mold services are the perfect solution. Recognizing the complexities involved in injection molding projects, we provide expert consultation to assist in transitioning from design to production seamlessly. Located in China, our extensive manufacturing network utilizes injection molding machines ranging from 90 to 830 tons, enabling us to produce parts of various sizes and complexities.

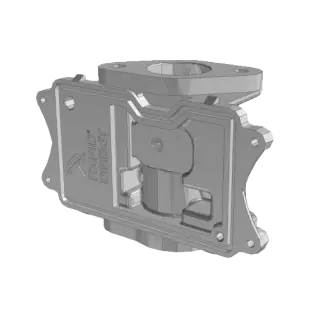

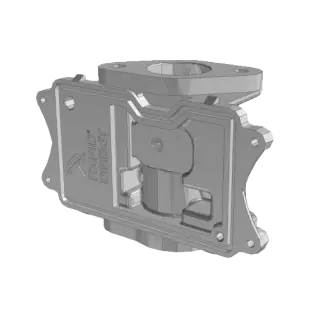

Injection Mold Tooling

- Aluminum and steel injection mold.

- Achieves detailed geometries.

- Ideal for mass production.

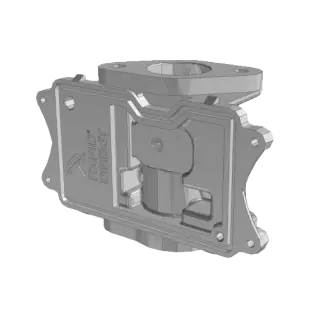

Injection Mold Tooling

- Aluminum and steel injection mold.

- Achieves detailed geometries.

- Ideal for mass production.

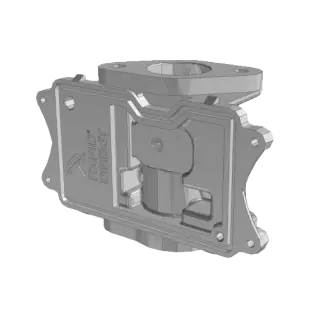

Injection Mold Tooling

- Aluminum and steel injection mold.

- Achieves detailed geometries.

- Ideal for mass production.

CNC Machining Materials

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

CNC Machining Surface Finishes

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

As Machined

As machined finish leaves the surface straight from the CNC machine, providing a cost-effective option with tool marks.

Tolerances for CNC Machining

| Information | |

|---|---|

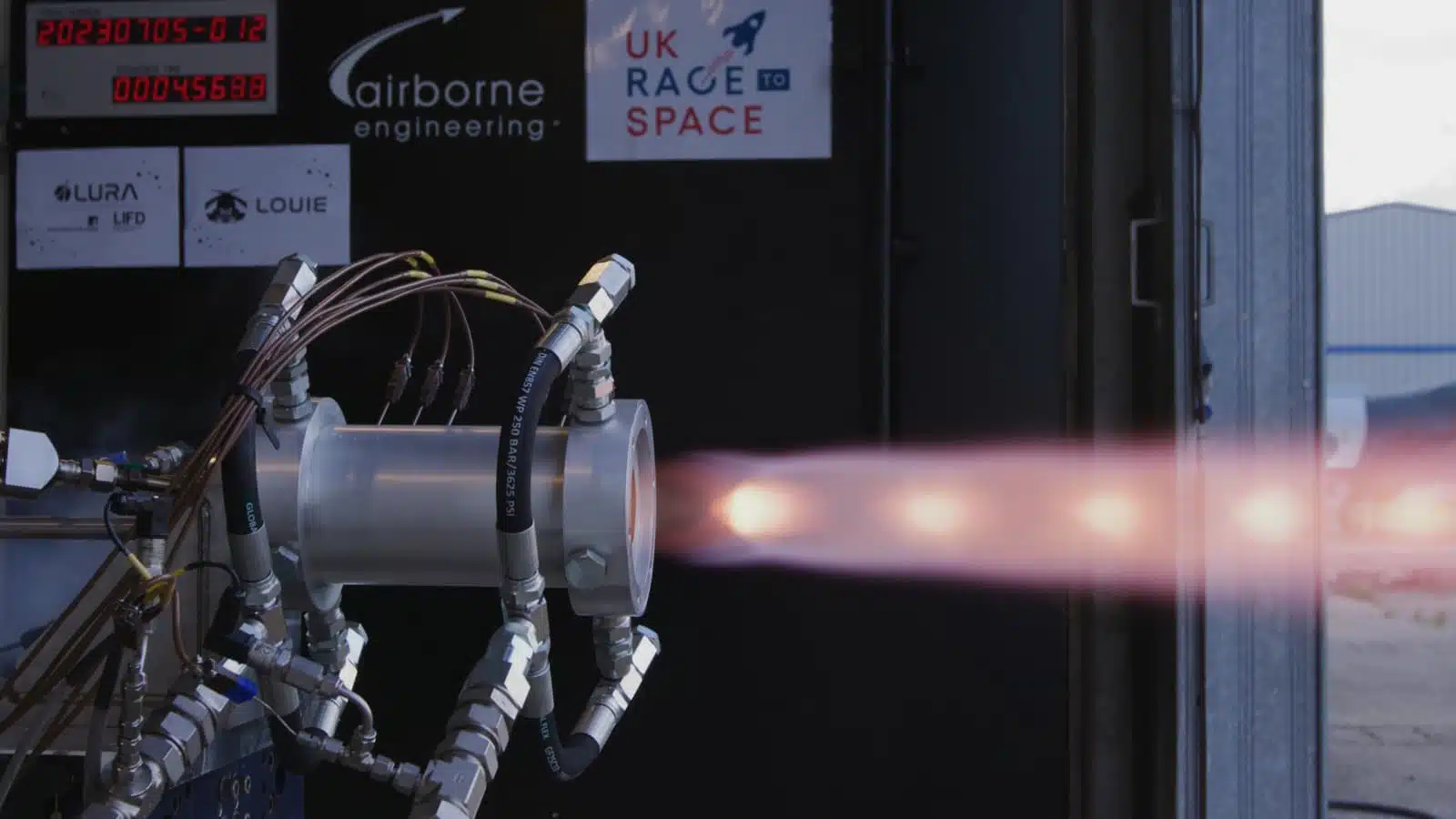

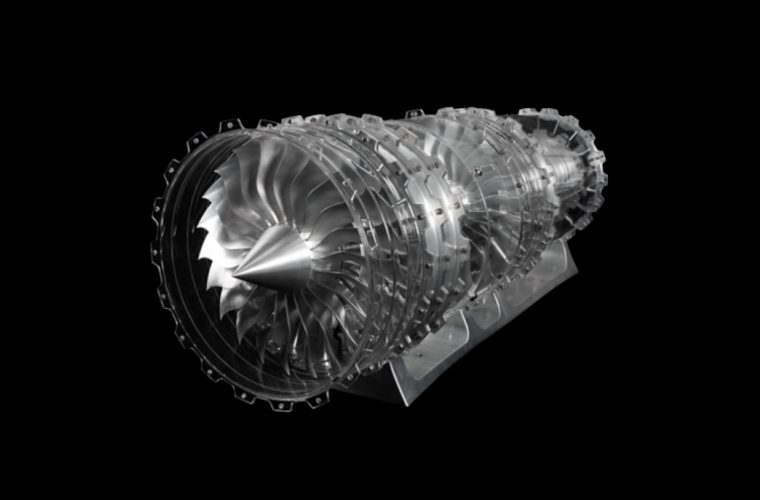

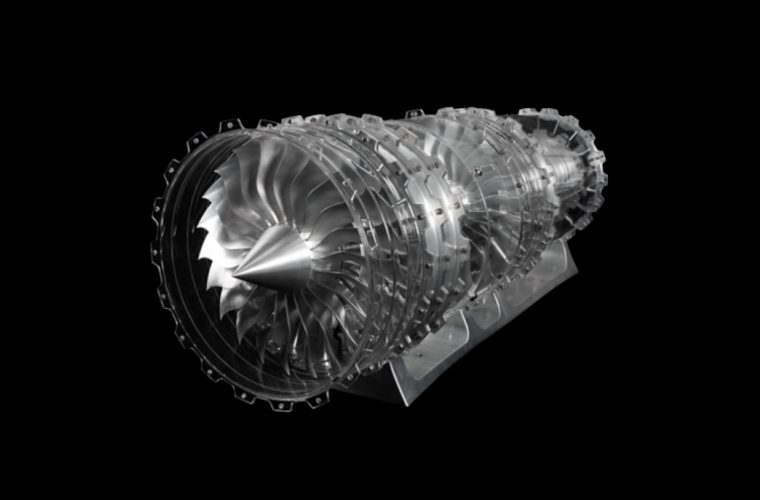

| Project Brief | LURA, the Leeds University Rocket Association, used RapidDirect’s 5-axis CNC machining and turn-mill compounding techniques to create intricate engine parts essential for their victory in the National Race to Space Propulsion Competition. |

| Industry | Aerospace |

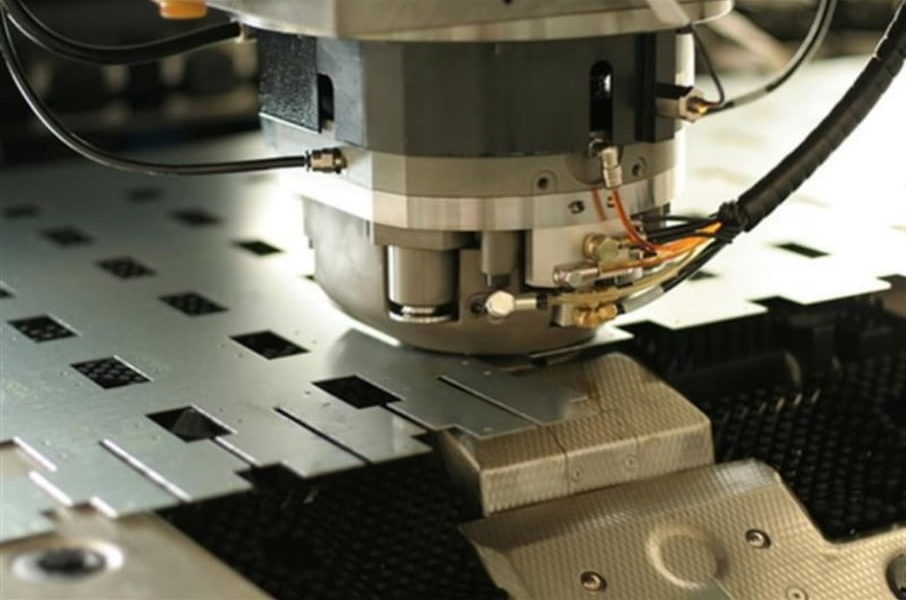

| Technology | CNC machining |

| Materials | Stainless steel, Aluminum |

| Surface Finishing | As Machined |

| Challenges | 1. Tight Deadline: The two-week span posed a challenge for delivering intricate parts. 2. Intricate Design: Rocket engine parts, especially combustion chambers, were deemed “manufacturable”. Besides, there are many oblique holes and grooves. 3. Tight Tolerance: The project required a challenging precision of +/-0.07 mm. 4. Material Issues: Unique thermal needs dictated using unconventional materials, especially in the combustion chamber. |

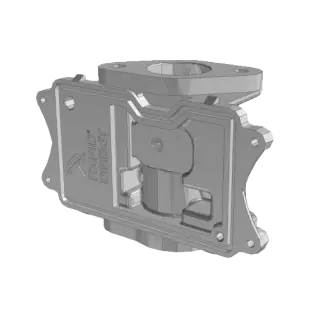

| Solutions | RapidDirect employs 5-axis CNC machining and turn-mill compounding techniques to accurately machine complex geometries, such as oblique holes and grooves. |

| The Result | The engine parts delivered within 7 days exceeded LURA’s expectations. |

Tolerances for CNC Machining

| Information | |

|---|---|

| Project Brief | LURA, the Leeds University Rocket Association, used RapidDirect’s 5-axis CNC machining and turn-mill compounding techniques to create intricate engine parts essential for their victory in the National Race to Space Propulsion Competition. |

| Industry | Aerospace |

| Technology | CNC machining |

| Materials | Stainless steel, Aluminum |

| Surface Finishing | As Machined |

| Challenges | 1. Tight Deadline: The two-week span posed a challenge for delivering intricate parts. 2. Intricate Design: Rocket engine parts, especially combustion chambers, were deemed “manufacturable”. Besides, there are many oblique holes and grooves. 3. Tight Tolerance: The project required a challenging precision of +/-0.07 mm. 4. Material Issues: Unique thermal needs dictated using unconventional materials, especially in the combustion chamber. |

| Solutions | RapidDirect employs 5-axis CNC machining and turn-mill compounding techniques to accurately machine complex geometries, such as oblique holes and grooves. |

| The Result | The engine parts delivered within 7 days exceeded LURA’s expectations. |

RapidDirect Injection Molding Solutions

RapidDirect’s custom injection molding services can seamlessly bridge the gap from prototyping to high-quality production. Our solutions accelerate product development cycles and ensure the delivery of superior injection molded parts, streamlining your path from concept to market. Experience efficiency and quality in every project phase with RapidDirect.

Rapid Prototyping

Address critical time-to-market needs by providing flexibility and economic efficiency for iterative development before full-scale production.

- Utilize aluminum or steel molds, which are perfect for rigorous testing and iterative processes.

- Typically single cavity, allowing for precise control during the prototype phase.

- Efficiently produce anything from a single unit to small batches (up to 2,000 units), facilitating quick market testing and design validation.

Rapid Prototyping

Address critical time-to-market needs by providing flexibility and economic efficiency for iterative development before full-scale production.

- Utilize aluminum or steel molds, which are perfect for rigorous testing and iterative processes.

- Typically single cavity, allowing for precise control during the prototype phase.

- Efficiently produce anything from a single unit to small batches (up to 2,000 units), facilitating quick market testing and design validation.

CNC Machining Surface Finishes

Equipped with over 50 advanced machines, capable of handling up to 830 tons, our network seamlessly manages projects from prototypes to full-scale production parts. Each engagement starts with a detailed injection mold quote to set clear expectations. Our project managers specialize in comprehensive manufacturing analysis and offer consultative design services to optimize each product for cost-effectiveness and functionality. The process concludes with detailed quality reports, ensuring all components not only meet but exceed industry standards.

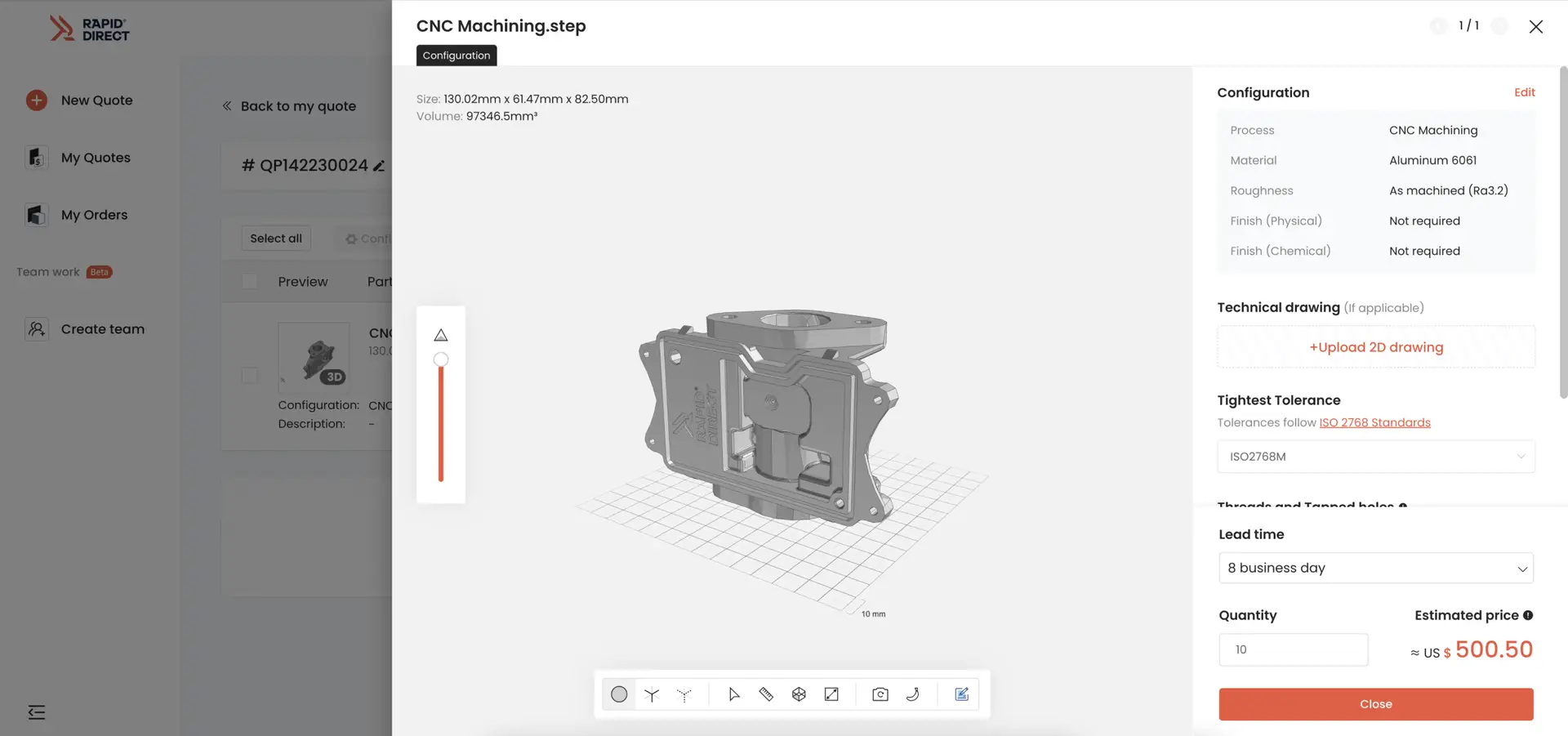

RAPIDDIRECT PLATFORM

Start Your CNC Machining Project

CNC Machining for Various Industries

RapidDirect’s CNC machining services cater to a wide range of industries, from automotive to aerospace, ensuring that every sector’s unique requirements are met with precision.

Success Stories of CNC Machining Projects

Why Choose Us

/01

High Quality Parts

Experience unparalleled precision in each undertaking. Our advanced milling processes ensure components adhere to tight tolerances, as tight as ±0.01mm, resulting in seamless assembly and operational excellence.

/01

High Quality Parts

Experience unparalleled precision in each undertaking. Our advanced milling processes ensure components adhere to tight tolerances, as tight as ±0.01mm, resulting in seamless assembly and operational excellence.

/01

High Quality Parts

Experience unparalleled precision in each undertaking. Our advanced milling processes ensure components adhere to tight tolerances, as tight as ±0.01mm, resulting in seamless assembly and operational excellence.

Ultimate Guide to CNC Machining

FAQs

RapidDirect’s Innovative Solutions

Dedicated Team for Silverback Project

Re-Evaluation of Tolerances

Innovative Machining Techniques

Fast-Tracking the Manufacturing Process